Laser Cleaning

A cleaner way of industrial multi-purpose cleaning, at a greater efficiency

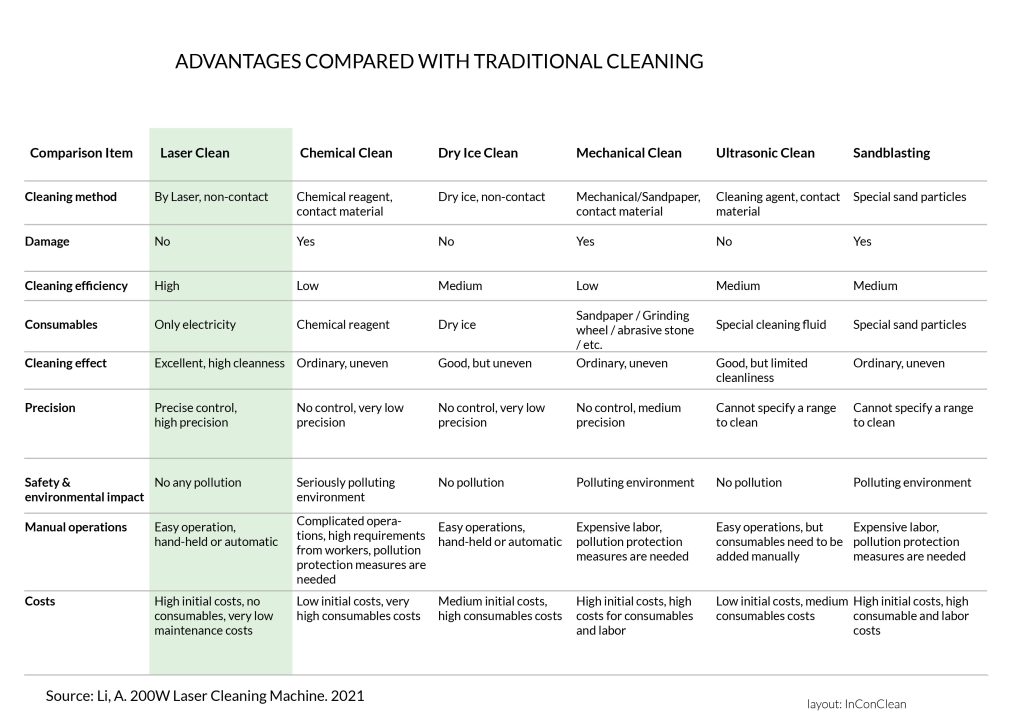

Laser cleaning is an innovative, clean, and environmentally friendly method that is utilized to remove rust, grease, stains a.s.o. from most types of materials and surfaces like for example steel-, rubber-, plastic-, glass-, concrete-, or wooden surfaces.

Laser cleaning is also an excellent option of rust removal from larger or smaller pieces of steel.

Using laser technique, surfaces can be cleaned effectively disregard if the surface is porous, smooth, glossy, rough, bent, coated, corroded or anything else. Laser cleaning can be used at areas which could be challenging to clean successfully by traditional methods. By the laser technique it is also possible to clean just a part of a surface or item with a precision much higher compared to traditional methods, and without causing any damage to surrounding surfaces or materials.

Environmentally friendly and effective

Compared to traditional methods like mechanical grinding or blasting with grit, soda, or dry ice, laser cleaning is causing minimal noise, dust, and heat, which contributes to a safer working environment, but also minimal environmental footprint.

Because of the contact- and dust-free method laser cleaning provides with minimal impact on the surface to be cleaned, it is an excellent choice on sensitive items, in sensitive areas, and in sensitive environments.

The mobile 200 W laser cleaning unit InConClean is using, is currently one of those with the greatest capacity on the Finnish market.

It is safe to use, with a high precision, and can be used both for the heavy industry, but also for smaller private projects.

The laser unit requires 230 VAC power supply.